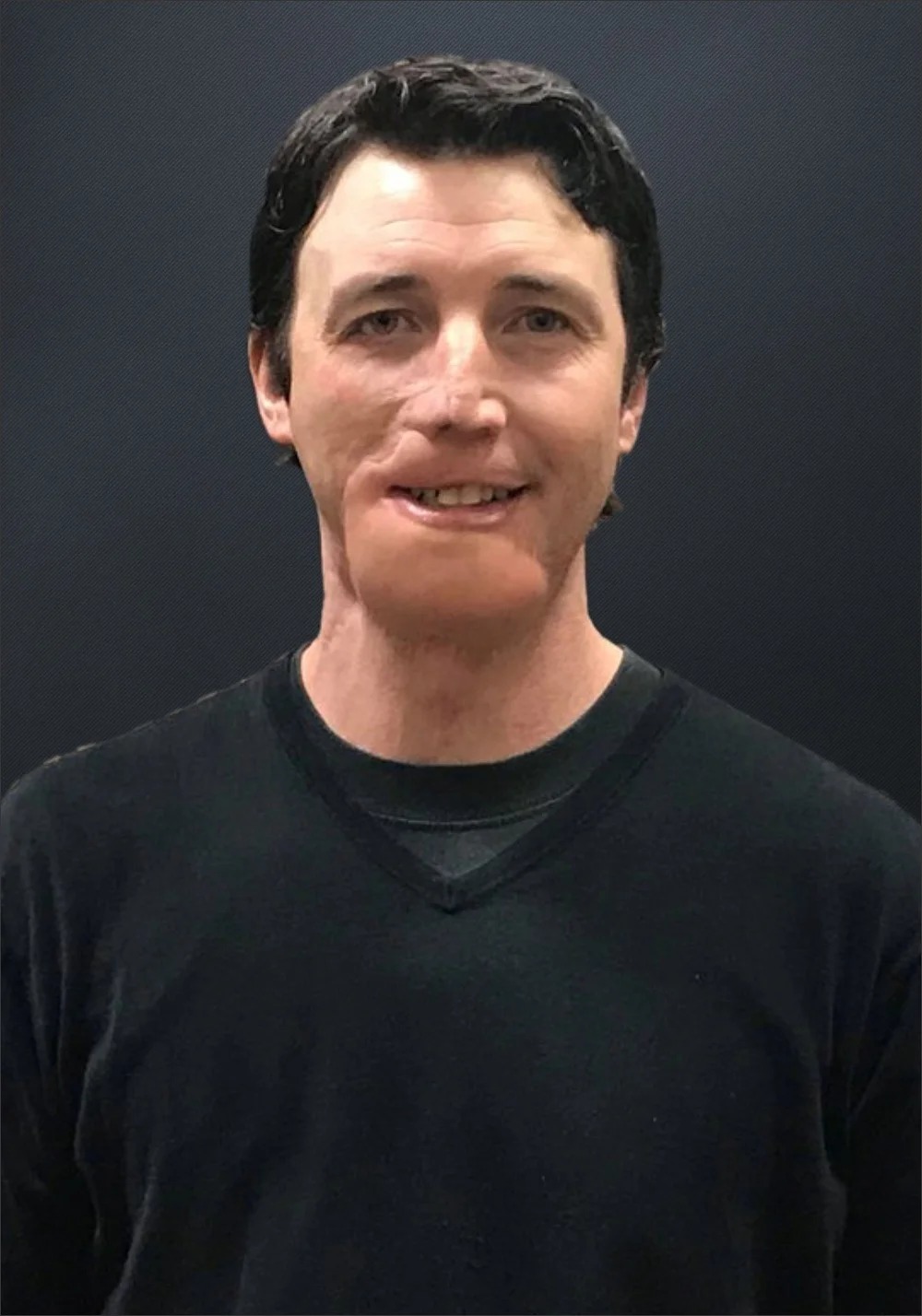

July 29, 1999. Saskatchewan, Canada. Curtis Weber, 17, working his third day at his first job outside his family’s grain bin business. The crew gathered under overhead power lines to discuss moving a steel hopper with their picker truck.

**𝗧𝗵𝗲 𝗰𝗼𝗺𝗽𝗮𝗻𝘆 𝗼𝘄𝗻𝗲𝗿 𝗶𝗱𝗲𝗻𝘁𝗶𝗳𝗶𝗲𝗱 𝘁𝗵𝗲 𝗿𝗶𝘀𝗸.** He said, “This is going to be an issue. We need to get this hopper over here and if we’re not careful somebody could be injured or killed.”

Fifteen minutes later, they made contact with that overhead line.

Curtis became the ground point as 14,400 volts surged through his body in three separate cycles. He suffered 3rd and 4th degree burns over 65% of his body and became a double amputee at age 17. Doctors gave him a 0% chance of survival.

**𝗛𝗲𝗿𝗲’𝘀 𝘄𝗵𝗮𝘁 𝗸𝗲𝗲𝗽𝘀 𝗺𝗲 𝗮𝘄𝗮𝗸𝗲:** This wasn’t a failure of hazard identification. They literally stood under the power line and discussed the risk.

**𝗧𝗵𝗶𝘀 𝘄𝗮𝘀 𝗮 𝗳𝗮𝗶𝗹𝘂𝗿𝗲 𝗼𝗳 𝗵𝗮𝘇𝗮𝗿𝗱 𝗰𝗼𝗻𝘁𝗿𝗼𝗹.**

Curtis reflects: “We had a brief chat about the hazard but didn’t spend any time on how to control it.”

NFPA 70E Section 110.3(H) requires risk assessment procedures that don’t just identify hazards—they demand implementation of risk control according to the hierarchy of controls. Yet how often do we see JHAs that become paperwork exercises?

**𝗜’𝘃𝗲 𝗿𝗲𝘃𝗶𝗲𝘄𝗲𝗱 𝗰𝗼𝘂𝗻𝘁𝗹𝗲𝘀𝘀 𝗝𝗛𝗔𝘀 𝘁𝗵𝗮𝘁 𝗿𝗲𝗮𝗱:**

“Hazard: Overhead power lines”

“PPE: Hard hat, safety glasses”

“Proceed with caution”

**𝗪𝗵𝗮𝘁’𝘀 𝗺𝗶𝘀𝘀𝗶𝗻𝗴?** The critical question: “What engineering or administrative controls will eliminate or reduce this risk?”

Proper controls might have included:

• Requesting utility de-energization

• Using non-conductive equipment

• Establishing exclusion zones

• Implementing a dedicated spotter system

**𝗧𝗵𝗲 𝗵𝗮𝗿𝗱 𝘁𝗿𝘂𝘁𝗵:** Identifying hazards without implementing controls is worse than doing no JHA at all, because it creates a false sense of security.

**𝗪𝗲 𝘀𝗵𝗼𝘄 𝗖𝘂𝗿𝘁𝗶𝘀’𝘀 𝘃𝗶𝗱𝗲𝗼 𝗶𝗻 𝗲𝘃𝗲𝗿𝘆 𝗡𝗙𝗣𝗔 𝟳𝟬𝗘 𝗰𝗹𝗮𝘀𝘀** we teach, from Amazon Web Services (AWS) to Exxon-Mobil to Salt River Project (SRP), as a sobering reminder that hazard identification without control implementation isn’t safety, it’s documentation theater.

Your JHA isn’t complete until you’ve answered: “How will we prevent this hazard from causing harm?” Not just “What’s the hazard?”

The difference between those two approaches? Sometimes it’s the difference between going home to your family and spending six weeks in a coma.

hashtag#NFPA70E hashtag#ElectricalSafety hashtag#JobHazardAnalysis hashtag#SafetyTraining hashtag#WorkplaceSafety hashtag#HazardControl , hashtag#SmartSafety

𝗪𝗵𝗲𝗻 𝗝𝗛𝗔 𝗕𝗲𝗰𝗼𝗺𝗲𝘀 𝗮 𝗖𝗵𝗲𝗰𝗸-𝘁𝗵𝗲-𝗕𝗼𝘅 𝗘𝘅𝗲𝗿𝗰𝗶𝘀𝗲: 𝗔 𝗟𝗲𝘀𝘀𝗼𝗻 𝗶𝗻 𝗛𝗮𝘇𝗮𝗿𝗱 𝗖𝗼𝗻𝘁𝗿𝗼𝗹